Toward a Water-Positive Industrial Ecosystem in Mar del Plata – Batán

The Mar del Plata – Batán Industrial Park depends on the Pampeano aquifer, a critical and overexploited water source that also supplies the surrounding urban area. With industrial water consumption ranging from 5,000 to 20,000 m³ per day, the aquifer is experiencing a sustained drop in its water table, increasing the risk of saltwater intrusion and putting the region’s long-term water security at risk.

One of the key drivers of this depletion is the extensive use of traditional impervious surfaces, which block natural infiltration and prevent aquifer recharge. This not only accelerates groundwater decline, but also leads to uncontrolled surface runoff, soil erosion, and inefficient stormwater management. Without strategic intervention, the park’s water footprint will continue to grow, threatening both environmental and economic sustainability.

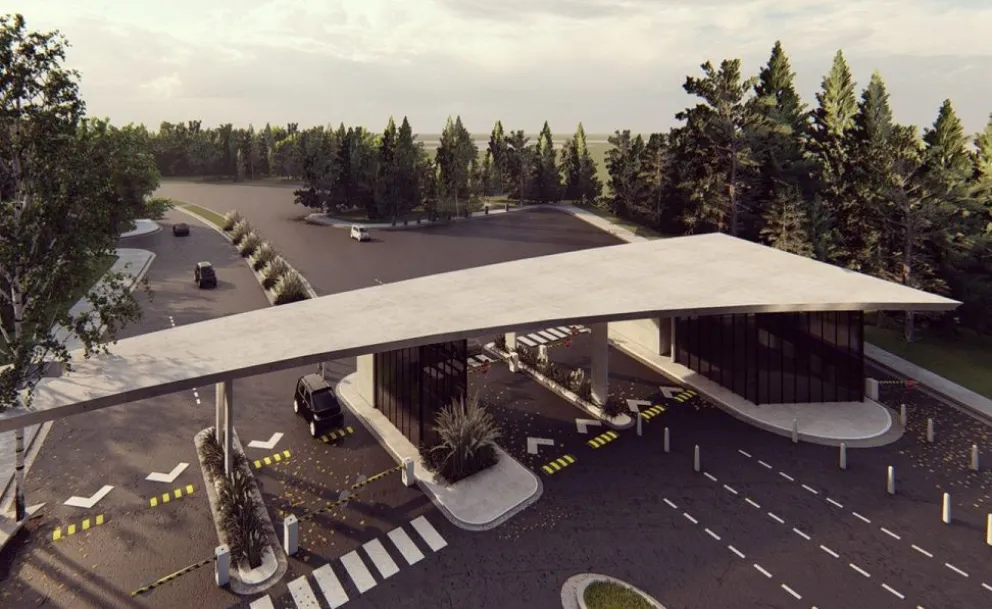

To address these challenges, the project proposes a water-positive transformation through a series of integrated, nature-based and technological interventions. Central to this approach is the replacement of impervious pavement with high-porosity permeable pavement designed for industrial loads. This infrastructure will restore the aquifer’s recharge function by enabling controlled infiltration, using layered filtration systems, drainage trenches, and geotextile membranes to manage flow, prevent clogging, and improve water quality.

In parallel, the initiative will implement real-time monitoring systems to track infiltration rates, groundwater levels, and overall system performance—ensuring continuous optimization and traceability in line with Volumetric Water Benefit Accounting (VWBA) methodology. This guarantees that the positive water impacts—such as infiltration, recharge, and runoff reduction—are measurable, additional, and verifiable.

To extend the scope of impact, the project also includes the development of a sustainable desalination plant at the nearby port, 20 km from the park. This shared infrastructure will supply treated water to both port operations and industrial users, reducing dependence on the Pampeano aquifer and aligning the park’s water use with circular and regenerative water strategies.

By combining nature-based solutions, smart infrastructure, and regional integration, this project positions the Mar del Plata – Batán Industrial Park as a scalable blueprint for water-positive industrial development in Latin America. It enhances local water resilience, reduces environmental risks, and demonstrates how strategic design can shift industrial zones from high-impact to high-contribution.

The Batán area, in the Province of Buenos Aires, faces a severe water imbalance due to the overexploitation of the Pampeano aquifer, excessive surface runoff, and industrial pollution. The continuous depletion of groundwater resources, compounded by inadequate drainage infrastructure, has intensified water scarcity issues and ecological risks in the region.

Overexploitation of the aquifer: The high industrial water demand has caused a sustained decline in the groundwater table, leading to a critical reduction in available freshwater supplies. The excessive withdrawal of water without adequate recharge mechanisms threatens the long-term sustainability of the aquifer and poses significant challenges for local water security.

Saltwater intrusion: The decline in groundwater levels has created a hydraulic imbalance that facilitates the intrusion of saline water into the Pampeano aquifer. This process gradually deteriorates water quality, making it less suitable for industrial and municipal use and increasing treatment costs for potable water supply systems.

Surface runoff and contamination: The widespread impermeabilization of the soil, caused by extensive paved surfaces and industrial development, prevents the natural infiltration of rainwater. As a result, large volumes of stormwater flow unregulated across the landscape, carrying pollutants such as heavy metals, hydrocarbons, and chemical residues into nearby water bodies, further degrading local water quality.

Lack of sustainable drainage infrastructure: The absence of engineered solutions for water retention and infiltration has led to chronic water mismanagement, increasing flood risks during heavy rainfall and exacerbating aquifer depletion during dry periods. Without proper interventions, the long-term sustainability of the region’s water cycle remains compromised, affecting industrial productivity and environmental resilience.

Rainwater harvesting and reuse

Collection systems on rooftops and paved surfaces, with storage tanks and regulated flow, can be integrated into non-potable uses such as landscaping, cooling towers, or sanitation. This reduces freshwater withdrawals and enhances local water resilience.

Industrial or municipal wastewater reuse

Advanced treatment systems (MBR, UF, RO) allow for internal reuse in cleaning, cooling, or industrial processes. Water exchange between companies within the park («industrial water symbiosis») can optimize use and create shared circular flows, reducing pressure on freshwater sources.

Process optimization for water efficiency

Re-engineering industrial processes to reduce water demand, implementing optimized cleaning cycles, and using automation for real-time control can lower the water intensity per product unit and reduce total demand.

Reduction of leaks and water losses

Implementing hydraulic sectorization, smart metering, and network rehabilitation helps recover otherwise wasted water and improves overall system efficiency.

Substitution of high-footprint water sources

Replacing potable or groundwater use with alternative sources like reclaimed or harvested rainwater reduces the overall water footprint and aligns sourcing strategies with science-based targets.

Water quality improvement and discharge control

Reducing pollutant loads (COD, nutrients, metals) through enhanced treatment or natural systems (constructed wetlands, biofiltration) contributes to Water Quality Benefits and helps regenerate downstream ecosystems.

Green infrastructure and permeability

The project will implement permeable pavement across the industrial park to reduce surface runoff and enhance natural infiltration. High-porosity materials such as porous concrete and interlocking pavers will replace traditional pavement, allowing rainwater to percolate into the underlying soil and replenish groundwater reserves. This solution is engineered to withstand heavy industrial loads while maintaining its permeability and long-term functionality.

The hydraulic design will incorporate multiple layers, including filtration layers, gravel beds, and geotextile membranes, to act as natural filtration and storage systems. These structures ensure that infiltrated water is gradually absorbed into the subsoil while avoiding sediment accumulation and clogging. Drainage trenches and perforated pipes will be embedded in the pavement system to capture and redirect excess water toward designated recharge zones, distributing it evenly across the site to prevent localized flooding.

An advanced monitoring system will be deployed to track infiltration rates, groundwater levels, and pollutant concentrations in real time. This data will enable proactive management and system optimization. In parallel, a structured maintenance plan will ensure long-term performance, including regular vacuum sweeping, pressure washing, sediment removal, and inspections to maintain optimal infiltration capacity and extend the pavement’s contribution to aquifer recharge and flood mitigation.

WASH and water access interventions

Improvements in sanitation and access to safe water for workers, along with water education for employees and suppliers, and community engagement initiatives, create measurable social impact aligned with WASH Benefit Accounting.

Sustainable desalination integrated with port operations

A sustainable desalination plant will be installed at the port, located 20 km from the industrial park, to supply treated water for both port activities and industrial users connected to the park. This infrastructure will use energy-efficient, high-recovery technologies and renewable energy sources to minimize its environmental footprint while generating a reliable, climate-resilient water source.

By integrating the industrial park with port operations through this shared desalination system, the project significantly reduces dependence on freshwater sources, lowers the combined water footprint of industrial and logistics operations, and ensures water security along the supply chain. This approach extends water stewardship beyond the industrial park, enabling measurable additionality across sectors and creating a replicable model of regional water-positive infrastructure.

Digital monitoring and traceability

The integration of IoT sensors and real-time data platforms enables predictive water demand management, quality control, and baseline simulation. This supports certified and auditable water benefit generation.

SDG 6 – Clean Water and Sanitation: Enhances water management by reducing contaminated runoff and increasing aquifer recharge.

SDG 8 – Decent Work and Economic Growth: Generates employment through construction, maintenance, and monitoring activities.

SDG 9 – Industry, Innovation, and Infrastructure: Promotes resilient and sustainable infrastructure in industrial settings.

SDG 11 – Sustainable Cities and Communities: Mitigates the negative effects of urbanization through sustainable drainage solutions.

SDG 12 – Responsible Consumption and Production: Encourages efficient water use and reduces industrial pollution.

SDG 13 – Climate Action: Increases resilience to extreme weather events, reducing the risk of floods and droughts.

SDG 14 – Life Below Water: Reduces contamination in coastal water bodies by preventing pollutant runoff.

SDG 15 – Life on Land: Protects water-related ecosystems through nature-based solutions.

SDG 17 – Partnerships for the Goals: Engages public, private, and industrial sectors in a collaborative, cross-sector solution.

The implementation of permeable pavement in the Mar del Plata – Batán Industrial Park is a strategic intervention designed to restore the hydrological balance of the Pampeano aquifer. By enabling controlled infiltration of rainwater through high-porosity, load-bearing materials and multi-layered filtration systems, the project directly contributes to groundwater recharge, reduces surface runoff, and enhances the park’s overall climate resilience.

Beyond improving water availability, this nature-based infrastructure minimizes flood risks, prevents soil degradation, and improves the quality of the recharged water by filtering out sediments and pollutants before they reach the aquifer. The integration of advanced monitoring systems—tracking infiltration rates, groundwater levels, and water quality—ensures continuous optimization and verifiable impact over time.

This initiative is aligned with the Volumetric Water Benefit Accounting (VWBA) methodology, guaranteeing that the generated water benefits are measurable, additional, and certifiable. By combining regenerative design, data-driven management, and industrial sector engagement, the project provides a robust, scalable solution for reducing water-related risks while creating long-term value for both industry and community.

More than a local sustainability effort, this project sets a new benchmark for industrial water stewardship in Latin America. It demonstrates how green infrastructure and collaborative governance can transform water-intensive zones into resilient, water-positive ecosystems—contributing to regional water security and climate adaptation goals.